Evergreen Pilot Project

A Case Study in Making Zero Energy Ordinary

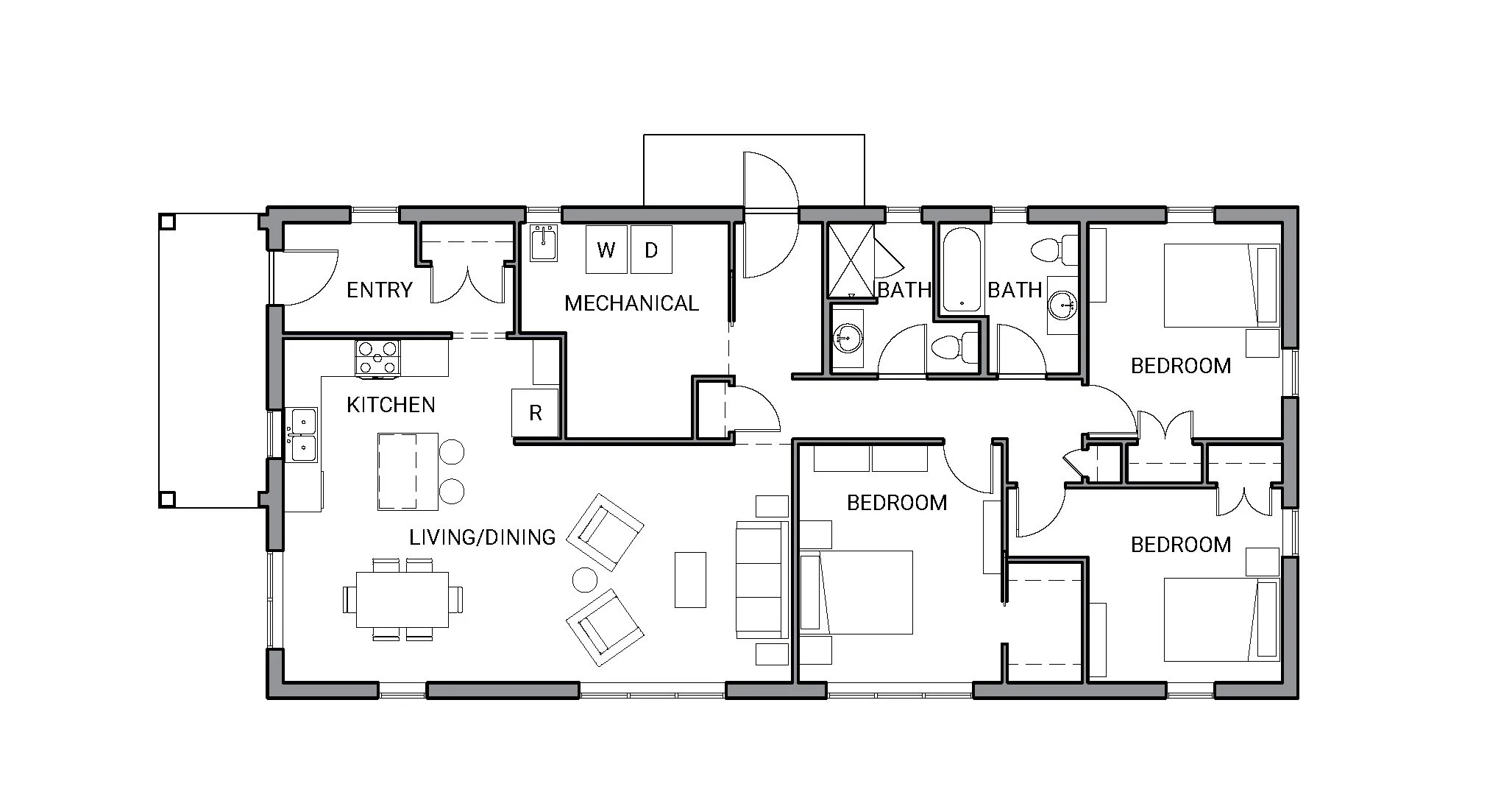

The Evergreen House is Just Housing’s one story, 3 bed 2 bath prototype. At 1500 sq. ft., it has enough space for a pair looking to age in place, a family of five, or anything in between.

The Evergreen House is Just Housing’s one story, 3 bed 2 bath prototype. At 1500 sq. ft., it has enough space for a pair looking to age in place, a family of five, or anything in between.

In 2023, the first Evergreen House was built by a nonprofit developer and then sold to a sustainability-minded retired couple. In its first year of occupancy, the house completely offset its energy consumption with solar-generated electricity production. In that year, the house used a third of the energy compared to a new code-built home in Duluth that was built and occupied at about the same time.

In a cold climate like Duluth’s, energy efficient housing is critical for the safety, comfort, health, and stability of residents. The Evergreen Pilot Project demonstrated that cost-effective green building and net zero energy performance can be achieved with clear design, assemblies and details – even with a builder who hasn’t built to this standard previously. We’re hoping this approach can extend far beyond a pilot project, and here we share why we believe it’s possible.

Design

“Green” can be a nebulous term. We define green as healthy, durable, energy efficient, and affordable. We use an integrated design process to help our work meet these four characteristics.

Adaptability, cost effectiveness, and ease of adoption are priorities in our quest to make green housing the new normal. To support these goals, we create solar-optimized floor plans that can be mirrored east-west, and design functional, iconic building forms appropriate for both rural and urban contexts.

Several performance goals inform our design process, including an air tightness target of 1 ACH50, and building energy loads that can readily lead to net zero performance with a reasonably sized PV array that will fit on the home’s roof.

We try to optimize each design for use of the sun’s energy, efficient plumbing runs, and compact but comfortable space allocations. The Evergreen floor plan is organized with the kitchen-dining-living space and bedrooms in the southern zones of the house, and the entries, utility room and bathrooms housed toward the north. A hallway between the living room, bathrooms, and bedrooms serves as the main circulation route in the house, both for people and mechanical services.

Mechanicals

Just Housing creates energy models of each design to estimate total building energy use, but also to size heating and cooling equipment. In all homes - but in high performance homes using air source heat pumps especially - mechanical equipment needs to be sized based on actual, calculated loads, rather than rules of thumb or area.

The calculated design heating load of the Evergreen House is 15,000 Btu/hr and the design cooling load of the Evergreen House is 8,200 Btu/hour. A 24,000 Btu/hr cold climate ducted air source heat pump (ASHP) provides heating and cooling in a single zone. A 5kW “supplemental” coil heater in the main supply ductwork can provide additional heat if the ASHP can’t meet the load under extreme cold. A heat recovery ventilator provides fresh air, and a heat pump water heater provides domestic hot water.

The mechanical room is in the center of the north side of the floor plan. Most of the ductwork runs through a dropped ceiling in the hallway. If this house had a higher air leakage rate and lower R values in its assemblies (meaning a higher heating load), fitting ductwork into this space might be difficult. But because our assemblies have decreased the heating load to less than half of what it would have been in a code-built design, the required heat can be delivered through much smaller ducts. With decreased duct sizes, fitting the ductwork in that soffit – and inside the thermal envelope – is no problem.

Construction

The Evergreen House was the General Contractor’s first high performance build, and their execution of the assemblies was excellent. They exceeded the air tightness requirement, with blower door test results beyond Passive House standards (0.41 ACH50).

When we say “ready to build” construction documents we mean it: we work hard to ensure that the drawings we provide are clear, well organized, and comprehensive. The general contractor let us know that our construction documents were easy to build from, and said that everything he needed to know was in there – a compliment so appreciated that we considered tattooing it on our foreheads.

You can learn more about our standardized construction assemblies here.

Occupancy

The homeowners moved into the house in November of 2023. Adjusting to any new home at the start of a Duluth winter can be a challenge, but the house stayed cozy and comfortable all winter, even with a few glitches in the controls of the heating and ventilations systems.

The systems were commissioned before the house was sold, but that doesn’t always guarantee perfect operation under real occupancy. The builder was attentive and addressed the issues.

Interestingly, the supplemental electric heater would come on at temperatures above what the setting for supplemental heat was supposedly set, so he (the homeowner) disabled the supplemental heat control sometime in January, 2024 and reported that the heat pump alone kept them comfortable for the rest of the winter.

The owners are thrilled with their home, and have committed to sharing their home with students, construction trainees, and the general public to help grow awareness of the need and solutions for more sustainable housing.

Energy Consumption

During design, we create two energy models: one as designed for ZNE operation, and another version designed to current energy code (right now we’re using 2018 IECC). This helps us dial in our assemblies and systems for zero energy operation (with solar panels), and low energy consumption even without PV. We design our homes to operate with about ⅓ of the energy that the house would require if simply built to code.

After the Evergreen House was built, we had the rare opportunity to compare its energy use with that of an actual house built to code. The Observation Hill House is just a mile away, built in 2023 and also occupied by two people. It’s built to the 2018 IECC, uses natural gas for heating, domestic hot water and cooking, has an HRV and has no air conditioning. It is 1152 ft2 and its tested air tightness was 1.53 ACH50. Just Housing is not affiliated with the design or construction of this comparison house.

Our energy model predicted an energy use index (EUI) for the Evergreen House of 25 kBtu/ft2. The HERS score predicted an EUI of 22 kBtu/ft2. Analyzing one full year of energy consumption data for both homes, we found that the Evergreen house outperformed our energy model and the HERS verification with an actual consumption EUI of 18 kbtu/ft2. With an EUI of 59 kBtu/ft2, the Observation Hill House uses more than three times the energy per square foot than the Evergreen House.

Read more about our energy analysis here.

Lessons and Conclusions

No project is without challenges. The project didn’t finish on time or on budget. We think it’s fair to say that most of the cost overruns and delays were due to the build taking place in the wake of the pandemic. The builder’s newness to high performance construction probably also contributed to the pace, as well as the fact that this was also the first project for a new nonprofit developer.

Even with cost overruns, this home was built for about $345 a square foot, not including land costs or garage, about 10-15% higher than reported costs of code-level homes built around the same time. These increased construction costs are offset by the lack of utility bills. Not only do the occupants pay essentially nothing for their energy, they won’t really be impacted by rising energy costs.

We ask builders for feedback on our plans and the process after a build is complete, an important step in continually improving our designs. After this project, the crew’s feedback helped us simplify our porch roof details.

We also engage in internal feedback. We’ve updated the design to be more comfortable for wheelchair users, which included widening the central hallway and sizing all interior doors to be 2’-10”. We learned not to place the ASHP outdoor unit on an entry slab, which creates slippery conditions in the wintertime. We will likely eliminate the ASHP supply air electric heater as supplemental heat, and use strategically placed independent electric resistance heaters instead.

Challenges aside, as Just Housing’s first built prototype, the Evergreen Pilot validates our approach to zero energy housing design and construction. Any new housing is expensive to build, but the first time you build is the least expensive time to build sustainably. We think we have a process that makes building sustainably cost-effective and repeatable.

See for yourself here: